Product and Quality

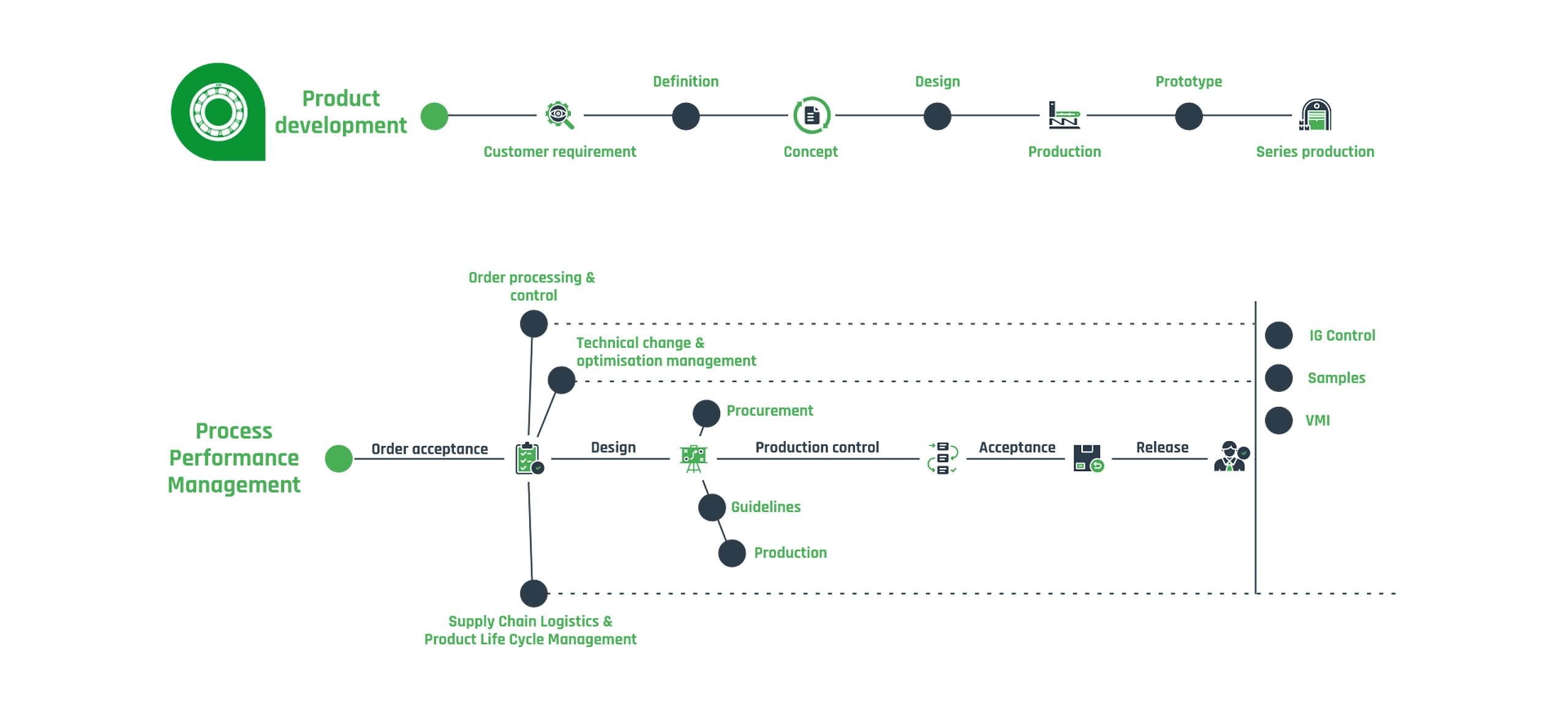

For us, quality with the associated quality management system doesn‘t only refer to the product, but to the sum of all processes behind its creation. This mindset helps us meet the requirements of our customers whilst also rising to individual objectives within the company. Each team member is an important part of our success as a business thanks to individual ideas and projects. Through continuous improvement processes and agile teamwork, we meet challenges sustainably and avoid mistakes in advance.

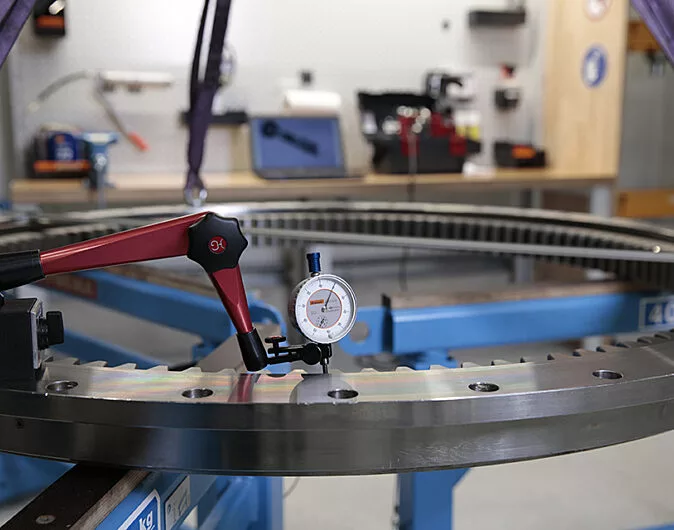

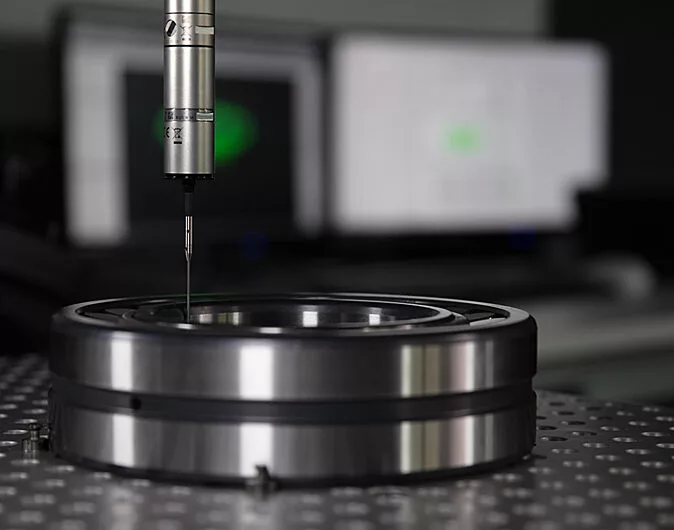

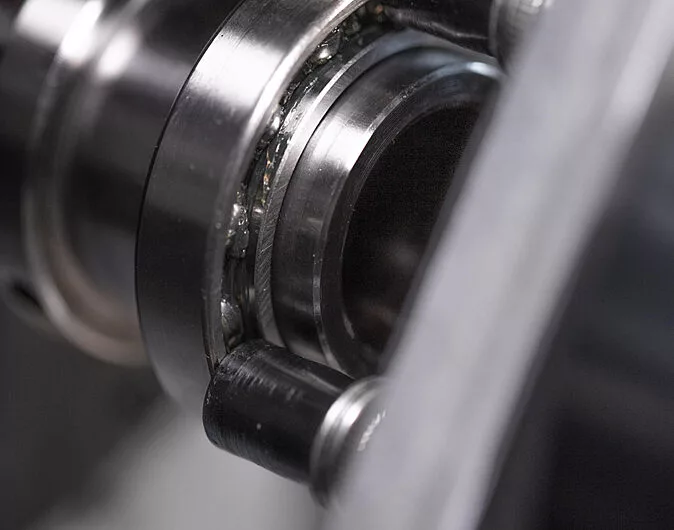

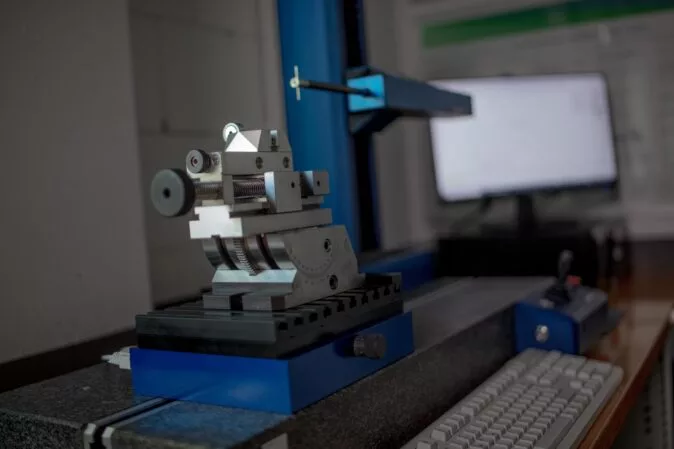

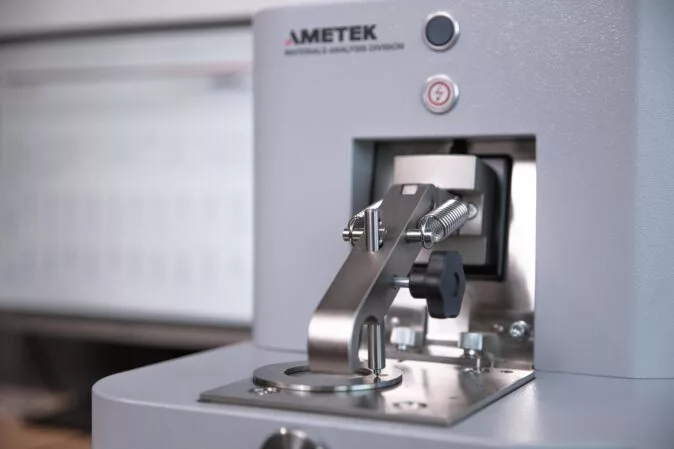

Our employees and their qualifications, flexibility and commitment are one of the central pillars of our success. Respectful collaboration within our team at all levels is very important to us. To guarantee our high quality standard for each and every product that leaves our premises, we rely on our established quality assurance both internally and externally, which go far beyond the standard level and requirements, working hand in hand with our engineering department. We carry out the quality control of our components with the utmost care and state-of-the-art measuring technology. This process ensures that we can guarantee reliable quality assurance at the highest level.